Introduction

As a

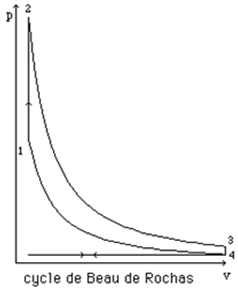

first approximation, the operation of gasoline or natural gas engines

can be represented by the so-called Beau de Rochas cycle, which is

reduced to four simple evolutions shown in the figure in the Watt

diagram of a cylinder:

As a

first approximation, the operation of gasoline or natural gas engines

can be represented by the so-called Beau de Rochas cycle, which is

reduced to four simple evolutions shown in the figure in the Watt

diagram of a cylinder:

- isentropic compression 4–1

This compression phase in a closed system begins after the inlet valves are closed and ends before ignition.

- constant volume combustion 1–2

Triggered at the end of compression, when the piston speed is null, combustion in a closed system is assumed to be fast enough to be considered instantaneous, and therefore at constant volume.

- reversible adiabatic expansion 2–3

This closed system expansion begins at the end of combustion and ends before opening the exhaust valves.

- constant volume cooling 3–4

At the end of expansion, opening the exhaust valves causes the pressure in the cylinder to drop suddenly.

We assume here that the emptying is instantaneous.

Such a model is not very precise but allows you to get a first idea of the performance of the engine.

In this guided exploration, we will study an industrial gas engine modeled with such a cycle.

Loading the industrial gas engine model

Loading the model

Click on the following link: Open a file in Thermoptim

You can also:

- either open the "Project files/Example catalog" (CtrlE) and select model m9.5 in Chapter 9 model list.

- or directly open the diagram file (gasMotor.dia) using the "File/Open" menu from the diagram editor menu, and the project file (gasMotor.prj) using the "Project files/Load a project " menu from the simulator.

The setting of this model requires a whole series of explanations.

The air flow sucked is 0.61 kg/s. It corresponds to a displacement of 21.9 l, and a rotation speed of 1500 rpm, for a suction temperature of 10 ° C.

Setting of the compression phase

The compression setting is as follows: closed system, with a set compression ratio equal to 12 and not calculated, and an isentropic efficiency equal to 0.95. The end of compression pressure is determined: 32.3 bar.

Setting of the combustion phase

The setting of the combustion chamber is different from those we have considered for the gas turbine: combustion takes place in a closed system, the air factor is known, equal to 1.6, and the downstream mass volume is set by the upstream point, combustion being assumed to be instantaneous.

Taking into account the strong cooling of the engine, necessary for technological reasons, the efficiency of the combustion chamber is worth 0.79, which means that 21% of the thermal power is lost.

The end of combustion pressure is 91.6 bar, and the temperature 1834 °C.

Setting of the expansion phase in a closed system

The expansion takes place in two phases: first in the closed system, until the valves open, then in the open system.

The expansion is therefore modeled by two expansion processes, the first, in a closed system, and the second in the open system.

The setting of the expansion phase in a closed system is also specific: as for compression, the expansion ratio equal to 12 is set, and an isentropic efficiency of 0.95 is taken into account.

The pressure at the opening of the valves is 3.98 bar.

Setting of the expansion phase in open system

At the end of expansion in a closed system, the exhaust valves are open, and expansion continues according to the same adiabatic law, up to atmospheric pressure, in open system this time, and without production of work, which justifies that the type of energy chosen is "other". The isentropic efficiency is taken equal to 1.

Engine performance calculation

Once the model is set, it becomes possible to calculate the engine performance.

It leads to a mechanical power of 427.4 kW and an efficiency of 37.56%.

Attention: the value of the motor efficiency can only be determined when the "combustion" process has been calculated.

Otherwise, it does not include the cylinder cooling heat, taken into account thanks to the chamber efficiency of 0.79.

Application exercises

Calculate engine performance for a compression ratio of 15

Efficiency and power have increased slightly.

Calculate engine performance for an air factor of 1.9

Return to the initial setting of the compression ratio by entering 12 instead of 15 for the compression and expansion ratios of the compression and expansion processes in a closed system, then click on Calculate in each of these processes.

Then modify the combustion setting by entering 1.9 instead of 1.6 for the air factor, and click on Calculate.

Then recalculate several times in the simulator screen until the balance stabilizes.

The efficiency has increased slightly, but above all the power is greatly reduced.

The influence of the compression ratio on power is less significant than that of the air factor, which directly affects the combustion temperature.

Conclusion

This exploration allowed you to discover a model of gas engine and the specific settings it uses.

You have been able to study the influence of compression ratio and air factor on engine performance.

However, as explained in the course, this model is very simplified and departs from the behavioral reality of reciprocating internal combustion engines.

A more realistic, but much more complicated model is proposed as an avenue for further study.

Modify the setting of the compression and the expansion phase in a closed system by entering 15 instead of 12 for the compression and expansion ratios, then click on Calculate in each of these processes.

Then recalculate several times in the simulator screen until the balance stabilizes.